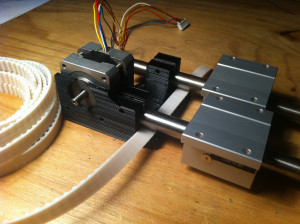

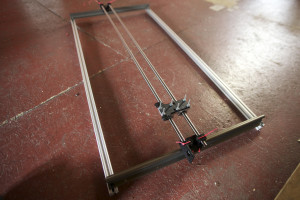

I’ve been inspired by the Lasersaur project to try building an XY table for laser cutting, Makerbotting, and light duty milling. The brackets, motor mounts and carriages are all 3D printed on NYCR’s Makerbot Thing-o-matic. Today I was able to put most of the pieces together for a dry fitting and found a few bugs — the carriages have too much play and will bind if pulled from the side, so the pull-pull belts will need to be moved to the inside of the rails, which will require all the carriages to be redesigned. The good news is that the printed teeth to engage the belt are well positioned to secure the belt under the rails without any additional hardware.

Lasersaur talk

At 19:3020:30 on this Monday’s extra special laser night, Addie and Stefan from Nortd Labs gave a presentation on the Lasersaur, their Kickstarter funded open source laser cutter. Safety goggles were not required, but fire extinguishers were.

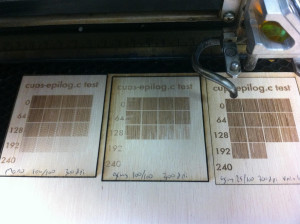

Laser cutting from the command line

One of NYCR’s most popular weekly events is Lunar Laser Mondays using our Epilog mini-35 laser cutter. The only supported system is Windows with CorelDRAW and Epilog’s closed source driver, which doesn’t seem right for a hackerspace. Luckily, AS220 Labs has figured out how to talk to the Epilog using PJL. I’ve written a command line tool, epilog, that will translate the Postscript file into commands for the cutter.

Continue reading »

WLAN Party!

We had an all-day / all-night LAN party at NYCR yesterday, with over a dozen players in ioquake3 on a mix of OS X, Linux, and Windows machines. There were lots of pizzas, highly caffeinated beverages and one combatant had a full-sized monitor for the extra old-school feel. Everyone was on the WiFi network (and the quake server was running in the router), so there were not any Ethernet cables, making it a WLAN Party instead.

Reinventing the key chain

I’m tired of my keys always jangling in my pocket, so I built a key-multi-tool out of a Crank Brother’s M5 bicycle tool. While I had the tool disassembled, I rearranged it so that the M3, M4 and #2 phillips were on the same side, which leaves room for five keys on the other side. It turns out other people had the the same idea. My keys still need cutting down since the key heads on the Medco keys are so large.

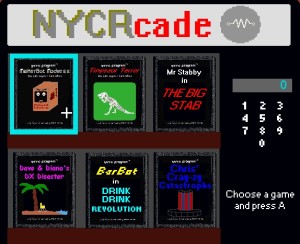

NYCRcade

30 days of watches

Inspired by Ranjit’s instrument-a-day (Make coverage), I’m writing a new wrist watch face every day for my progamable inPulse watch (more background). The full sources are posted online for others to build on.

Day 1 was a fixed point 3D rendering engine with a rotating Utah Teapot, day 2 was a rolling odometer or aviation altitude ticker display and day 3 is a 24-hour analog clock. This last one still needs some work.

The inPulse watch is a great platform to hack on. It has an ARM7, 32 KB of flash and 8 KB of RAM, Bluetooth, a buzzer, an OLED screen and a button. Not much by today’s standards, but plenty to play around with. The programming environment is very much like a microcontroller; no multitasking, no dynamic memory, and very constrained memory/cpu. That is, of course, what makes it so much fun. From very basic timekeeping contraction devices to today’s smartwatches, clocks have certainly evolved so much. If you wanna know more about the history or watch news, visit James Hampton-Smith’s blog called SpotTheWatch.

Continue reading »

First steam!

First steam from Trammell Hudson on Vimeo.

We’ve been rebuilding an Astoria two group espresso machine at the NYCR space and have finally made steam and espresso with it after a few weeks of cleaning. The pressure-stat triggered at 1.5 bar and the boiler held the pressure just fine. The pump produced precisely 9 bar. The hot water tap even looked sort of clean! Now that all functionality has been restored it is time to start on the computer control.

The controller will need:

- Six relays (two heater elements, two group heads solenoids, one fill valve and one pump motor)

- Three thermocouples (one per group head and one for the main boiler)

- Two pressure measurement (one main boiler up to 3 bar, one for the group heads up to 15 bar)

- At least two switches

- A multi-line LCD

- Ethernet

- RFID reader

- An iPhone or Android app?

First peek at the Arduino Art show

(More photos coming tomorrow)