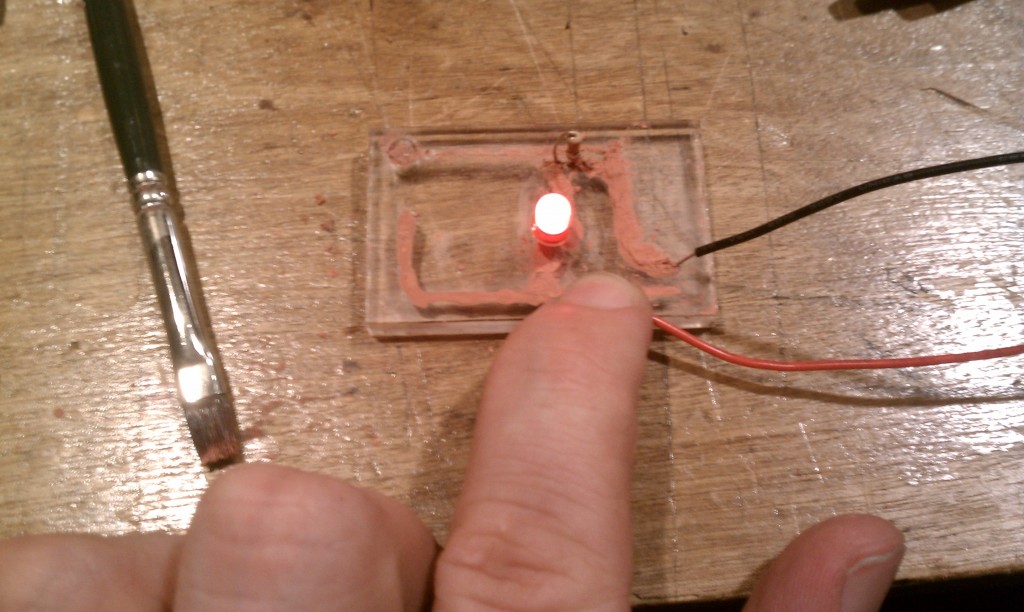

Conductive Ink Success

I’ve recently had success in making a conductive ink using a fine copper powder suspended in an acrylic airbrush medium. This paper on conductive epoxies was really the key to getting this ink working.

The paper shows that etching the metal filler slightly before mixing it with the binder improves the conductivity of the ink. In this test I first used ammonium persulfate as the initial etching solution. After decanting off the resulting copper sulfate solution, the powder was then washed with deionized water. The wet powder was then mixed with an acrylic airbrush medium to make the resulting ink.

There is still quite a bit of experimentation to be done, but this is a very encouraging result!

If you are interested in conductive inks you should look at some of these projects:

- This ink made at Pumping station one that results in bulk silver

- Kit-of-No-Parts Amazing projects

- And of course openMaterials

[…] Conductive Ink Success […]

[…] voorafgaand aan het mengen met het bindmiddel te laten reageren met ammoniumpersulfaat, werd ontdekt dat de geleiding veel beter ging. De behandelde koperdeeltjes werden gescheiden van de […]